SC-FlexHoses – FLEXIBLE HIGH-PERFORMANCE SUPPLY HOSES FOR STRONG ABRASIVE WEAR

To compensate for changes in length due to temperature fluctuations in long pipelines, special expansion joints that are also lined with cast basalt or alumina ceramic are usually manufactured. The alternative to such expansion joints – also referred to as compensators – are flexible hoses into which a ceramic, e.g. alumina ceramic, is vulcanised as wear protection. The greatest advantage of flexible hoses over expansion joints is that they can compensate movement in several directions. This completely eliminates the high risk of sticking or caking on the gliding surfaces. Wherever hoses are exposed to strong abrasive wear, the SC-FlexHoses provide optimal wear protection.

CHARACTERISTICS

- Material: Rubber, SBR/NBR anti-wear, anti-static mixture

- Hexagonal or square (tetragonal) shape

- Steel wire reinforcement as well as copper wire mesh to ensure the hose is conductive.

Flexible wear-resistant hose systems are used for the following operating conditions and/or requirements, among others:

- Compensation for differences in length or height, for example due to thermal effects or for moving plant components

- Vibrations

- Absorbing kinetic energy, for example when conveying coarse bulk goods like fluff or gravel with large particle sizes at high speed

Media like sand, suspensions, lime, or dust can be fed without any problem, and therefore economically, due to the special design of the highly wear resistant alumina ceramic mosaic tiles encapsulated in the rubber through vulcanization.

Biomass power plants (both shapes for pipelines and digestion plants: pumping seepage water)

TYPICAL INDUSTRIES WHERE CERAMIC WEAR-RESISTANT SC-FlexHoses ARE USED

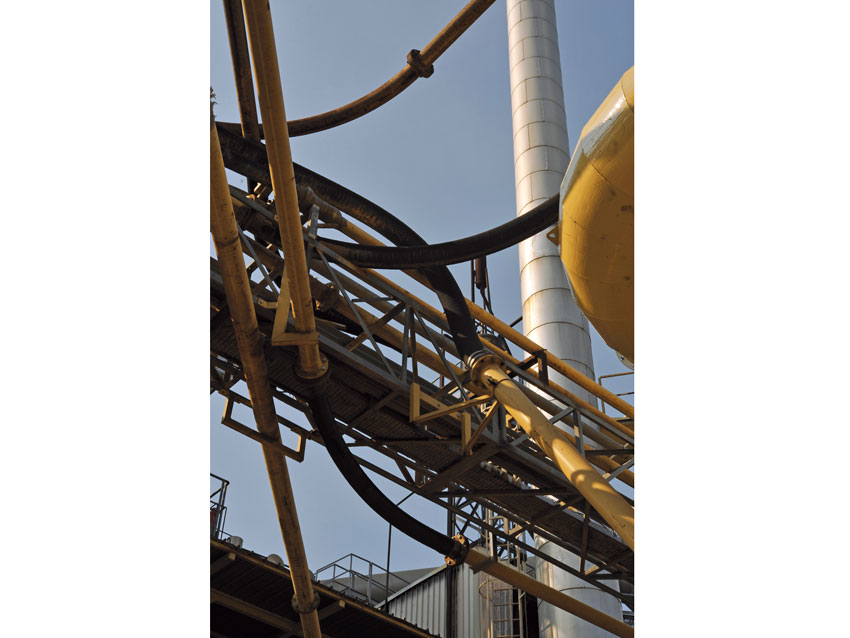

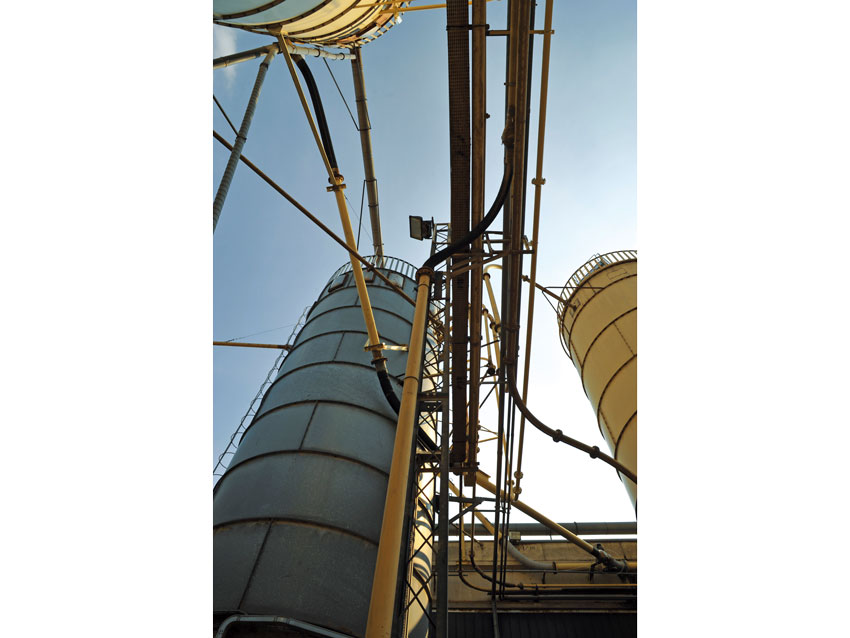

- Cement plants: Conveying replacement fuels like coal or ash (burners, supply lines, silos)

- Coal power plants: Replacement fuels (supply lines)

- Mineral processing: Conveying bulk materials like sand, quartz, or lime (supply lines)

- Steel mills: Conveying coal, coke, or lime, for example (supply lines, arc furnaces)

- Chipboard plants: Conveying wood dust to the burner

- Biomass power plants: For example to convey seepage water to the digestion plant

AREAS OF APPLICATION

Flexible wear-resistant hose systems are used for the following operating conditions and/or requirements, among others:

- Compensation of differences in length or height,

- for example due to thermal effects or for moving plant components

- In case of vibrations

- Absorbing kinetic energy, for example when conveying coarse bulk goods like fluff or gravel with large particle sizes at high speed

Media like sand, suspensions, lime, and dust, for example, can be conveyed without any problem, and therefore economically, due to the special design. This is accomplished by the high wear resistant alumina ceramic tiles that are encapsulated in vulcanised rubber.

ADVANTAGES

- Long service life due to ceramic wear protection

- Small bending radius

- Early leak detection possible using the integrated signal wires

- Can be used immediately: radii and angles are flexible and you can choose the flanges. This means the hoses can easily be connected to existing lines

TECHNICAL CHARACTERISTICS

- Operating pressure: 10 bar

- Minimum burst pressure: 3.2 times the operating pressure

- Temperature service range: -40°C to max. 120°C

- Inner Ø: 20 to 305 mm (larger diameters are also available on request)