NO CHANCE FOR ABRASION.

TH. SCHOLTEN GMBH & CO. KG – TAILOR-MADE CUSTOMER SERVICE

FOR INDIVIDUAL WEAR PROTECTION SOLUTIONS

EXPERT ADVICE – INNOVATIVE MATERIALS FOR EVERY TYPE OF WEAR – COMPETENT SERVICE

Expert analysis and consulting

A great deal of experience and expertise is needed to ensure state-of-the-art wear protection and professional lining with the proper material. Trouble-free production is only possible through reliable protection against damage due to wear.

We first conduct a detailed analysis of all factors contributing to wear. After analysis, we offer our customers individual advice on the type of wear protection and countermeasures when documenting the current state of wear. We continue to provide advice throughout the project so that the customer is up to date on the project status at all times.

Using modern 3D scanning, we determine the data that is missing but decisive for the planning, production, and installation of the new plant components. Our engineers then develop an individual wear protection model based on the results. Our employees ensure proper installation on-site or can act as supervisors to train and instruct site staff as an alternative.

Avoiding time-consuming and costly leaks is increasingly becoming an important issue, which the Th. Scholten company counters with their specially developed early warning leak detection system that monitors the plant components online 24 hours a day and triggers an alarm in time before a leak occurs.

Modern WEAR PROTECTION materials from Th. Scholten

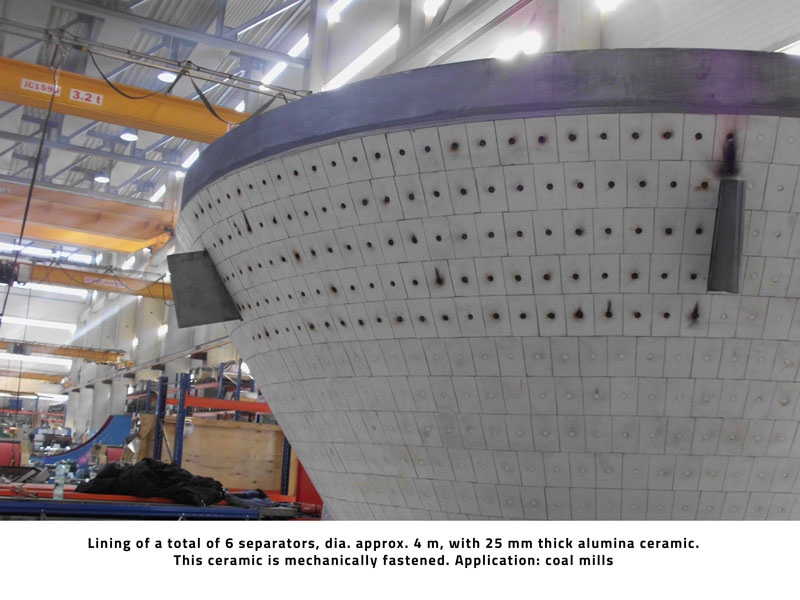

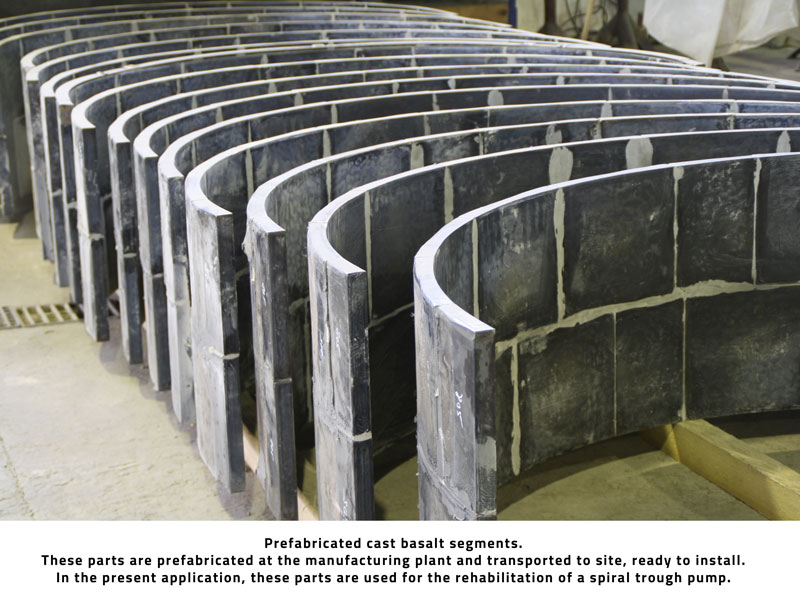

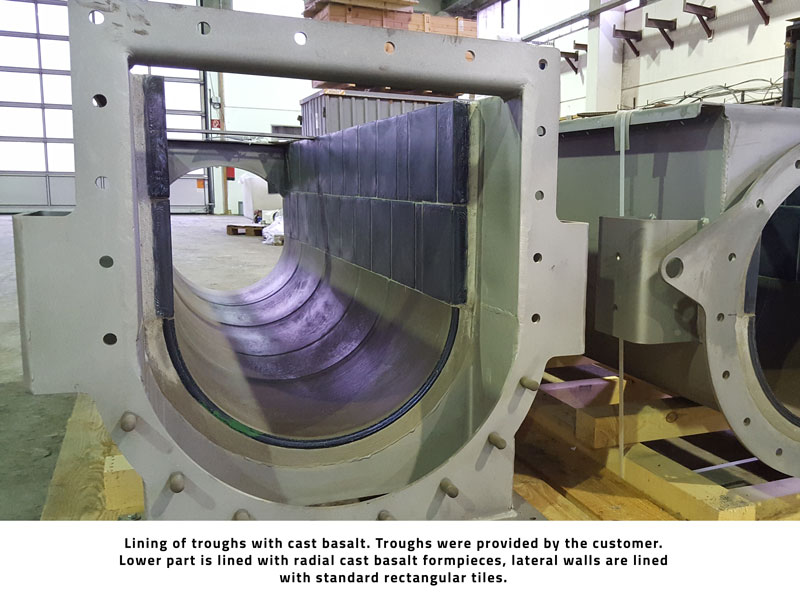

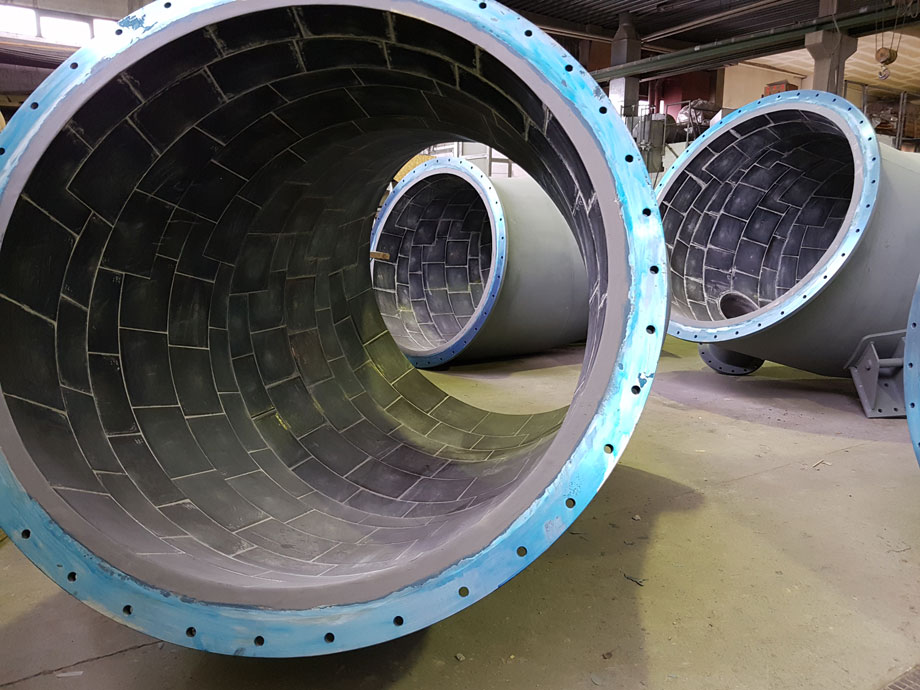

The Th. Scholten GmbH & Co. KG works with a broad portfolio of ceramics and other materials that are used for the professional lining of pipelines and plant components on-site or in our plant. To ensure a long service life of the components to be protected, it is particularly important to select and use the appropriate material for every single type of wear. We then use a single material or a combination of materials, from classic cast basalt to hard ceramic, in an efficient wear protection system.

Competent service and professional project management

The services offered by the Th. Scholten GmbH are based on decades of practical field experience and ensure that our customers are always on the safe side regardless of the type of wear protection problem:

- Precise analysis of all sources of wear

- Individual project planning with a preventive wear factor analysis

- Development of the optimum wear protection measures

- In-house installation of wear protection linings on plant components and pipelines

- Production of precisely shaped and fitted wear protection components in our factory

- At site: expert installation of the components produced and/or the installation of wear protection linings on immovable plant components, carried out by our specialist team of fitters

- On-site supervision and training of customer teams

- Short-term scheduling possible seven days a week

- Consultation by telephone and in person for technical and practical wear problems provided by our experts (technical department, installation department)

DELIVERY

The Th. Scholten GmbH & Co. KG determines the optimum and most economical materials for the customer’s particular project and matches them specifically to the corresponding type of wear. Thanks to our efficient service organisation, we can react quickly and flexibly to requests from our customers, and deliveries are made promptly. Our experienced employees provide support in all matters relating to the best possible delivery solutions.

- Supply of complete, wear-resistant lined plant components, including steel casings,

g. piping, cyclones, chutes, etc. - Supply of precisely shaped and fitted wear protection linings for installation on site

- Installation on site by our specialist fitters or the deployment of senior fitters (supervisors) to provide the customer’s staff with installation instructions.

ON-SITE INSTALLATION

Our experienced, multilingual installation teams install the optimum wear protection lining at the customer site in large-scale and permanently installed plant components such as bunkers, silos, cyclones, or trough chain conveyors. Our employees are available as competent contacts for every technical field.

- Immovable plant components and plant components that cannot be transported due to their size or for reasons of cost are lined directly at the customer site.

- If desired by the customer, we offer an all-inclusive package: Scaffold construction, sandblasting to prepare the surface to be lined, disassembly, and proper disposal of worn linings

- Optional: Supervision to instruct and supervise the customer’s own team of fitters.

- Regular checks and maintenance conducted by installation specialists,

if necessary, even 24/7 around the clock

PRODUCTION IN THE FACTORY

Anything that can be economically transported by road can be manufactured and lined in our factory. This includes the entire range of a wide variety of plant components such as pipelines, cyclones, hoppers, trough chain conveyors, etc.

We would also be happy to repair your worn out components. If necessary, we can also perform any steel metalworking necessary. In this case, you will receive a refurbished, repaired, and surface-treated plant component already equipped with wear protection that is ready for installation.

Since we have the most common sizes available in stock, we can deliver a wide variety of wear protection materials at any time on short notice. This means there will generally be enough time available for us to refurbish plant components in our factory during a planned shutdown of the plant.

SUPERVISION

The Th. Scholten GmbH & Co. KG also offers its expertise to its customers when the customer would like to have the wear protection installed by its own staff or by partners.

- Project briefing by a senior fitter or supervisor

- Transfer of his or her years of experience in the form of training and instruction of third parties

- This in turn ensures an appropriate supply of wear protection material and proper installation at the site

- Overall supervision and acceptance of the project in the interest of the customer

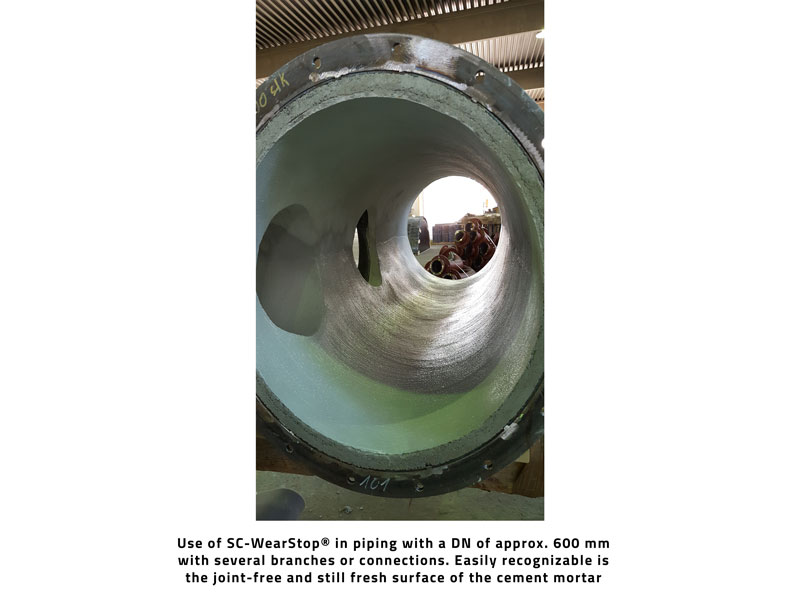

PIPELINE CONSTRUCTION

Together with its customers, the Th. Scholten GmbH & Co. KG develops solutions for pipeline projects all over the world. The company has more than 70 years of experience in almost every sector of industry. First, it is necessary to conduct a detailed analysis of the plants and their specifications. Regardless of whether it is a project subject to the EU Pressure Equipment Directive or a standard design – we offer our customers support and advice from planning and implementation to the on-time delivery of complete components to the installation site. If there are special corrosion protection requirements, we also offer special surface coatings in addition to our ceramic materials.

- Determination of the potential for wear by defining the type, size, and properties of the materials to be conveyed as well as the conveying speed

- Definition of the appropriate wear material or combination of wear materials

- Technical documentation including production drawings, allowances, and 3D scan

- Delivery of labelled, fully tested, and documented piping components with CE markings

- Installation of entire pipelines: The design of the pipeline components requires complex calculations (required wall thicknesses, categorisation according to the EU Pressure Equipment Directive, and according to the operating parameters)

- If desired, installation of an early warning leak detection system

In the event of special operating conditions or requirements, special systems such as the following will be used:

Flexible, wear-resistant hose systems with high wear resistant aluminium oxide ceramic tiles that are encapsulated in vulcanised rubber.

- Compensation for differences in length or height, for example due to thermal effects or for moving plant components

- For non-friction connections

- In case of vibrations

- When conveying coarse bulk goods like fluff or gravel with large particle sizes at high speed

- Advantages: long service lives through ceramic wear protection, small bending radius, immediately applicable due to flexible selection of the radii or flange (easy to connect the hoses to existing lines)

- Optional: Equipped with an early warning leakage detection system using an embedded signal wire