ZIRCONIA CERAMIC – MANIFOLD APPLICATIONS AGAINST EXTREME WEAR AND HIGH TEMPERATURES

MANUFACTURE AND PROPERTIES

Zirconia ceramic is a material in the group of mixed ceramics and is produced by binding different oxides: aluminium, zirconium, and silicon oxide are molten in an electric arc furnace at approx. 2.000°C. Mixed crystals form, which provide this material with its distinct characteristics:

- High strength and hardness

- Extremely high wear resistance

- 50% Al2O3 content (Al2O3 group of materials)

Due to its mineralogical composition – approx. 50% corundum, 32% zircon, and a glass phase content of approx. 18% – and its method of production, zirconia ceramic is frequently referred to as fused corundum, sometimes also as “zirconia-reinforced alumina ceramic”.

PRODUCT RANGE AND FORMATS

The smelt fused in the electric arc furnace can be cast into a variety of moulds:

Standard tiles with edge lengths ranging from 150 to 500 mm and wall thicknesses from 20 to 100 mm

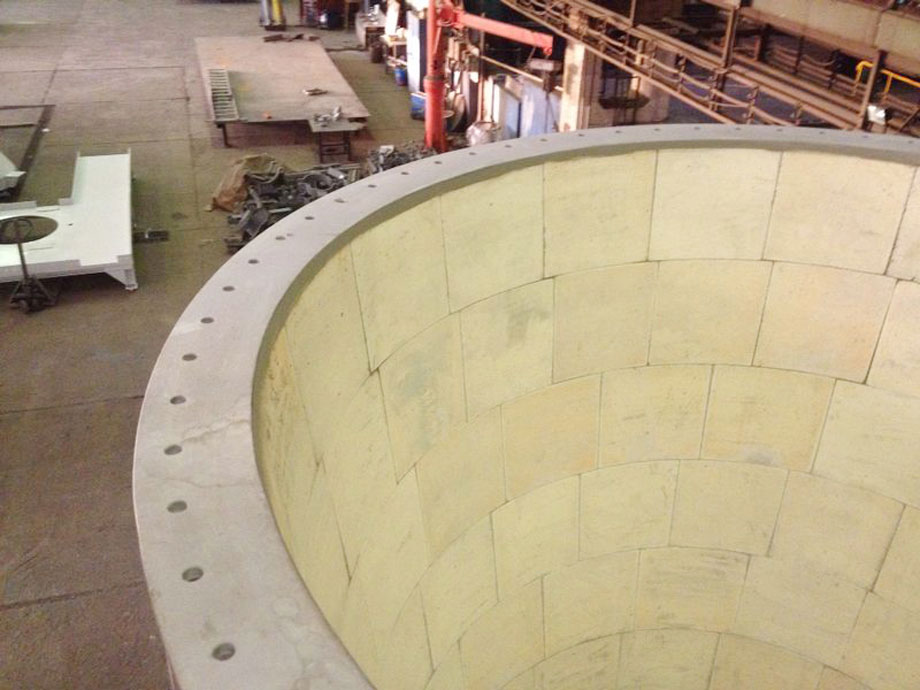

Furthermore, straight pipes and elbow segments are produced as standard products with wall thicknesses ranging from 17 to 25 mm and inner diameters from 50 to 350 mm. Radial tiles can be manufactured as well.

Because the material is shaped by casting, special formpieces can be produced, e.g. for lining pumps, cyclones, etc.

The temperature limit is approx. 1.000 °C.

AREAS OF APPLICATION

Zirconia ceramic is characterized by its particular hardness, mainly due to its corundum content.

The main areas of application are therefore applications characterised by extreme abrasive wear and/or impact wear as well as high temperatures.

Thanks to the flexible shaping options and the variety of fastening methods, this material is suitable for lining nearly all types of plant components.